Shear Cracks Explained (How Shear In Reinforced Concrete Works)

Shear is quite a complex topic. Still, to this day, I am learning new things about it on a regular basis.

And it’s shocking to me how many engineers I’ve worked with are unaware of the basic fundamental of shear in reinforced concrete structures.

In this short article, I’ll give an introduction to the most important basics (at least to me) of shear, why shear cracks happen and how we add shear reinforcement, so that (hopefully) rc elements don’t fail in shear.

Let’s get into it.

Why And How Do Shear Cracks Develop In Reinforced Concrete Beams?

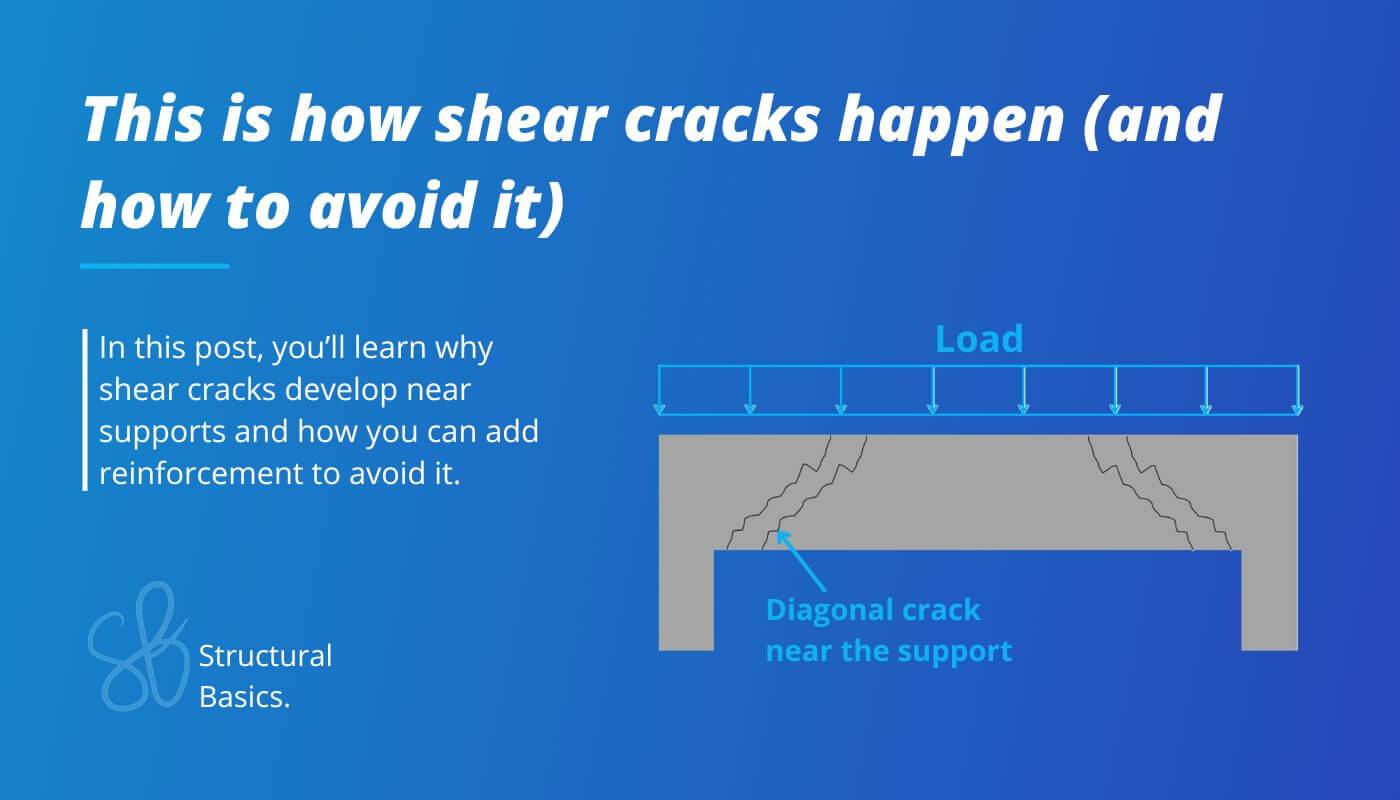

The best way to start understanding shear better is by looking at shear failure of rc beams – or in other terms, where the beam cracks when the shear forces are too big.

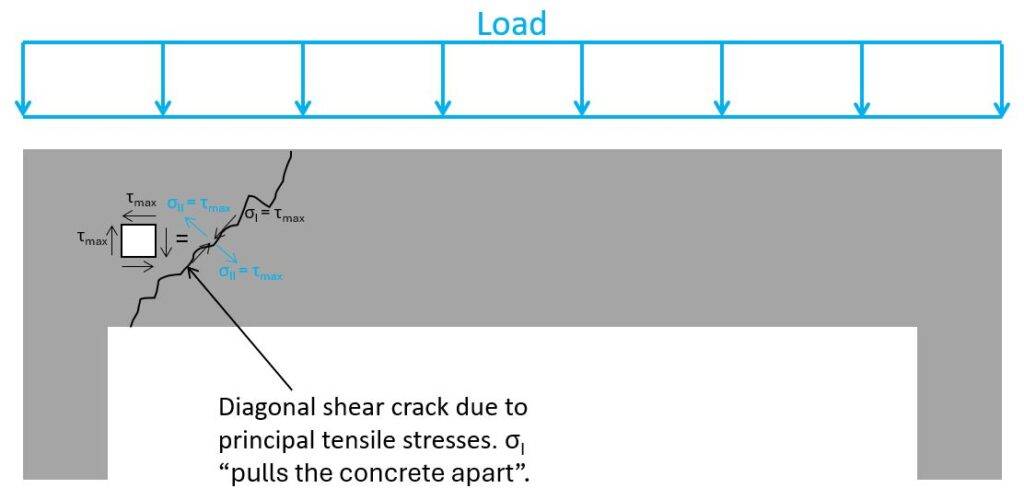

Shear cracks of beams exposed to a line load appear as diagonal cracks near the supports. Why at the supports? Because that’s where the shear forces are the biggest.

Let’s dive into why this is.

This line load leads to a bending moment and a shear force when we cut the beam close to the supports.

The bending moment leads to normal stresses with compression in the top and tension in the bottom, while the shear force V leads to a shear stress distribution which is 0 at the outermost fibres and has its maximum value τmax at the ceontroid of the cross-section.

The shear stress τmax at the centroid is equal to the principal stresses.

You might have already seen now, why we get the diagonal cracks. The principal tension stresses σI basically pull the concrete apart.

How Stirrups Avoid Shear Cracking

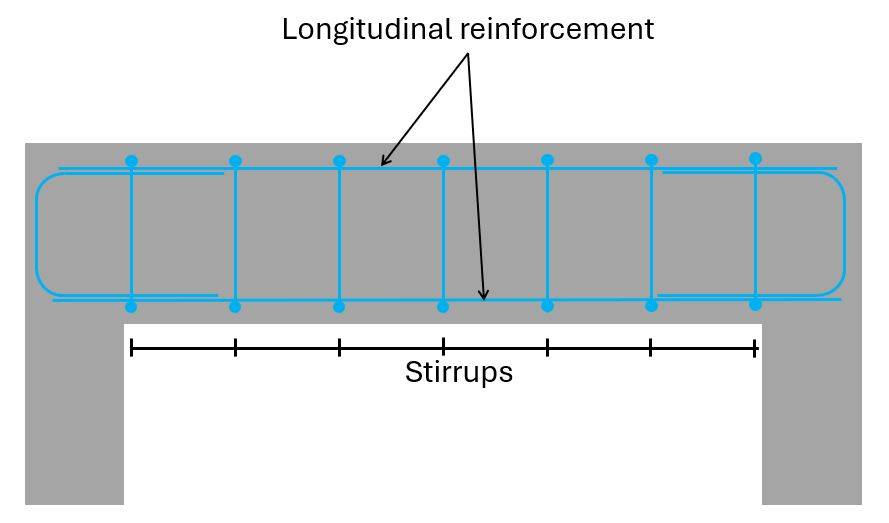

Alright, to solve this “issue” of diagonal cracking, we add stirrups.

These stirrups basically help “hold the beam together”.

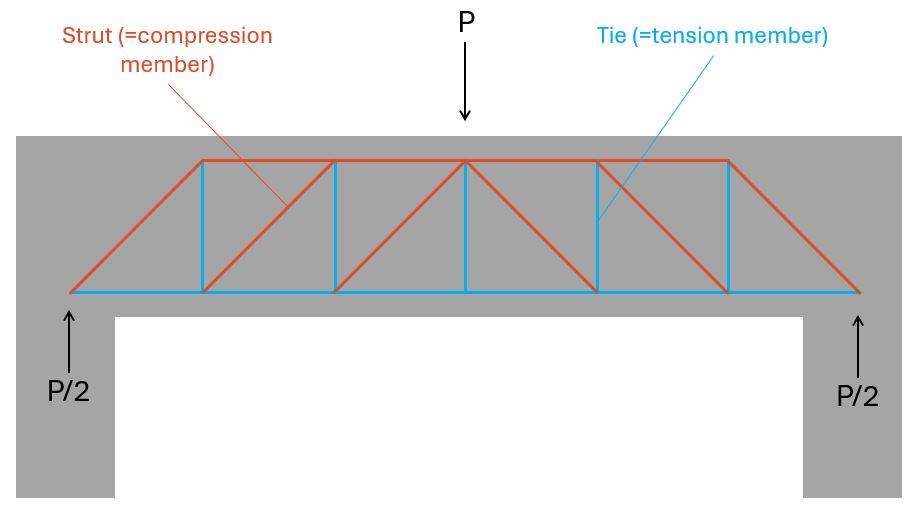

Now, the beam can actually take up tension forces vertically. This means that we can use a strut & tie model / truss model to transfer the vertical loads to the support.

With this strut & tie model, the stirrups have to be designed to resist the vertical tension forces and the concrete needs to be checked for the compression forces of the struts.

Hope this explanation helped understand shear a bit more. Writing this, I researched a lot and learned a bunch myself. In structural engineering, there is always more to know.

Below, you’ll find in depth articles of how to verify shear without and with shear reinforcement according to Eurocode..

Shear Verification Without Shear Reinforcement

I have already written an in-depth article about shear verification without shear reinforcement. You can check it out here. ↓↓

Or, if you prefer video format, you can check out my YouTube tutorial.

Shear Verification With Shear Reinforcement

Learn how to design and verify reinforced concrete beams for shear with reinforcement from my in-depth newsletter article on Substack.

Final words

This was one of these endless weekends of studying and researching about shear in rc elements. In the end, it took me 10 hours to write this post. But it was fun and I can say that I understand shear on a deeper level now.

I hope it helped you understand shear a bit better.

And if you struggle to understand shear. I feel you. It’s very complicated. And it’s OK to admit that you haven’t understood it.

If you don’t want to miss any new structural design tutorials, then subscribe to our free weekly newsletter.

Or subscribe to my YouTube channel for regular updates.

Laurin Ernst

![Rafter Roof Design [Step-By-Step Guide]](https://www.structuralbasics.com/wp-content/uploads/2022/04/Rafter-Roof-Design-1-768x439.jpg)