12 Types of Columns in Buildings [The MOST Used]

Are you looking for an alternative column type than in-situ concrete, or you just want to learn about all types that exist?

I get it, by looking at buildings or structures we don’t really see what material or geometry is used because they are in most cases covered by insulation and cladding.

But also the word column in civil engineering is not 100% clear.

Because there are different categories of columns. In statics, we talk about static systems of columns, while on construction sites columns are differentiated by the material and geometry.

Let’s break it down in this post. We’ll show all types of columns, from static systems to concrete columns, and show the advantages and disadvantages of each one of them.

Without further ado. Let’s talk COLUMNS.

What Is a Column?

Columns are vertical structural elements which resist vertical and/or perpendicular loads. They are characterized by acting in compression. However, tension and bending are also possible. The loads travel through the elements and get distributed further to the next column, slab or foundation. Columns mostly support other columns, beams and slabs.

Columns in Buildings

Columns are primarily used in a building to transfer the vertical loads down to the foundation and then into the soil.

Most of us think of concrete as the material for columns.

So it’s no surprise it’s the first in the list!😀

Let’s find out what other materials are used and what geometries are common for columns.

1. In-situ Concrete Column

In most countries, in-situ concrete columns are the way to build columns.

Concrete is cheap and has great structural properties.

And in-situ concrete technology allowed us to build infrastructure projects and skyscrapers such as the 828 meters high Burj Khalifa.

In the picture above, you can see in-situ concrete columns. What’s special about the in-situ concrete columns is that they easily connect to neighbouring elements such as walls, because they are casted at the same time.

This makes the structure watertight.

As the concrete is extremely weak in tension, steel rebars (reinforcement) is additionally required. To connect 2 columns with each other, reinforcement from one column is extended to another.

You can see these rebars in the picture as well. 👀👀👀

Pros and Cons

Advantages

Disadvantages

Concrete is a cheap material to build with

Concrete is unsustainable, high CO2 emissions during production of cement

Construction companies and structural engineers have good knowledge about concrete

Heavy structure -> bigger foundations are required than for steel or timber

Concrete has great compressive strength properties

Longer construction time for in-situ concrete columns than other materials

Good fire resistance

Watertight structures (underground, water dams, foundations, etc.)

Where are in-situ concrete columns used?

- Housing

- Office buildings

- Garages

- Infrastructure projects

- Underground structures (garages, basements, etc.)

- High-rise buildings

- etc.

2. Steel Column: I/H Cross-Section

I/H Cross-section are the most used structural steel columns in the building industry. They have been around for a long time, so structural engineers, builders and authorities know how to build with them.

In the picture above, you can see that the steel columns support a wooden roof.

The steel columns are also exposed to the environment, which means that additional coating is required in order to protect the steel from corrosion.

Pros and Cons

Advantages

Disadvantages

Easy to design, Builders know how to build with it

Steel is very unsustainable, high CO2 emissions during production for new and recycled steel

Fast assembly -> reduced construction time

Expensive building material (dependent on country)

Lightweight building material

Maintenance cost due to corrosion protection systems (coatings, paintings)

Easy design for disassembly

Low fire resistance

Where are steel columns with H/I sections used?

- Warehouses

- Sports halls

- Supermarkets

- Open parking garages

- Skyscrapers

- etc.

Want to learn how to design steel columns?

Then check out this guide, where we walk you through step-by-step!

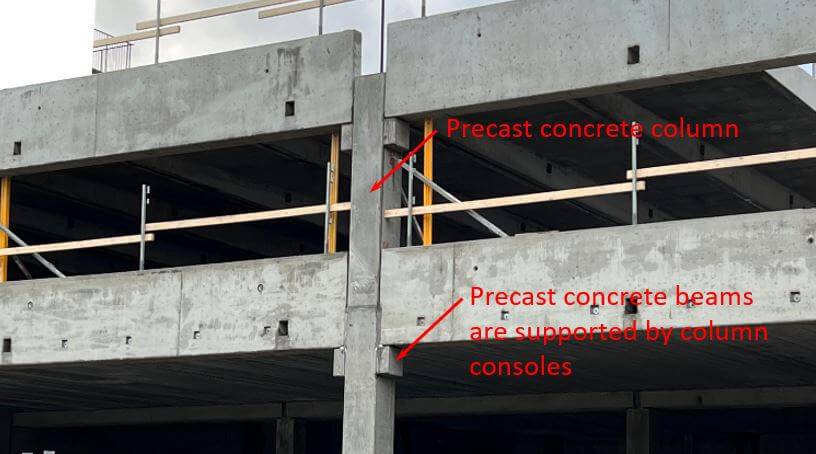

3. Precast Concrete Column

As construction schedules are getting tighter, precast concrete columns are a great way of speeding up the total construction time, if the material concrete is used.

Precast concrete columns are, as the name says, casted in a factory, then delivered to the construction site and lifted in place.

This type of column has especially been popular in the Scandinavian countries.

Pros and Cons

Advantages

Disadvantages

Concrete is a cheap material to build with

Concrete is unsustainable, high CO2 emissions during production for cement

Fast assembly of precast columns

Heavy structure -> bigger foundations are required than for steel or timber

Concrete has great compressive strength properties

Good fire resistance

Where are precast concrete columns used?

- Housing

- Office buildings

- Garages

- High-rise buildings

- Warehouses

- etc.

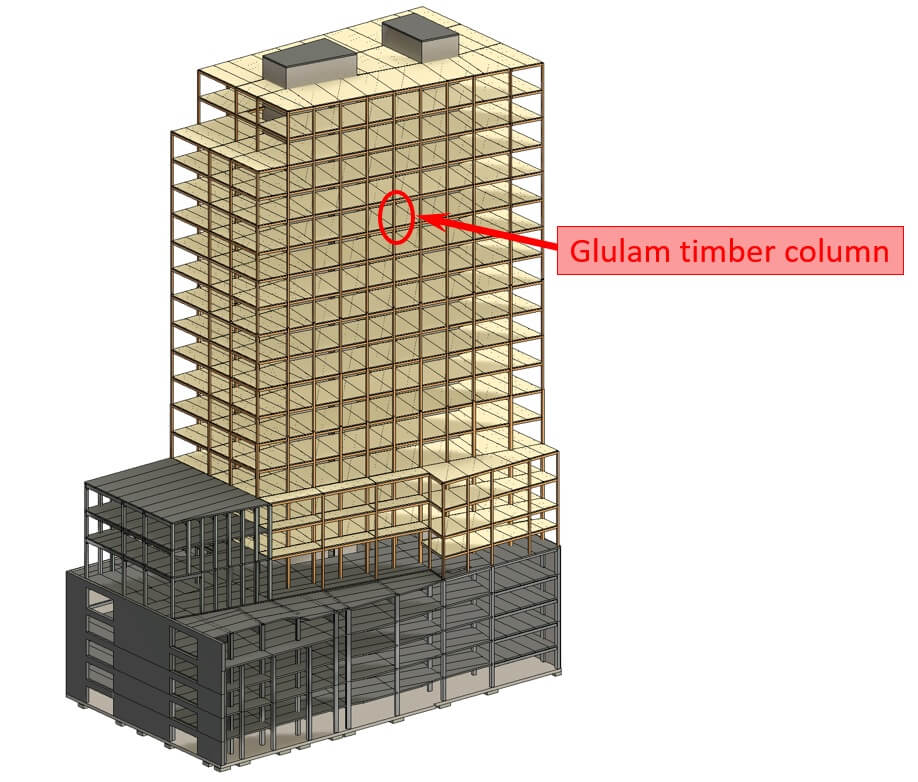

4. Glulam Timber Column

The trend that timber gains in popularity is partly also due to the “new” technology of glulam.

Glulam is short for glued laminated timber. So timber laminates are glued together.

This leads to stronger timber elements which can take more loads.

In the picture above, you can see that glulam timber columns are used in a high-rise building.

A couple of impressive timber high-rise buildings have already been built, such as the Mjøstårnet.

This is an 85,4 m tall timber building. Impressive! Isn’t it?

Pros and Cons

Advantages

Disadvantages

Easy to design, Builders know how to build with it

Steel is very unsustainable, high CO2 emissions during production for new and recycled steel

Fast assembly -> reduced construction time

Expensive building material (dependent on country)

Lightweight building material

Maintenance cost due to corrosion protection systems (coatings, paintings)

Easy design for disassembly

Low fire resistance

Where are glulam timber columns used?

- Housing

- Sports halls

- Canopies

- High-rise buildings (as we have seen👌)

- Charging stations for EV’s (I have seen loads of them in the past 2 years)

- etc.

Want to learn how to design glulam columns?

Then check out this guide, where we walk you through step-by-step!

5. Structural Timber Column

Structural timber columns were the main types of column that humans built with for centuries, before steel and concrete were discovered!

Due to fires that erased many cities on the world, structural timber got more and more avoided.

However, structural timber is coming back. Building with timber is very easy and sustainable. A small timber cabin or canopy can be built by 1 or 2 people.

OK, so let’s have a look at the pros and cons.

Pros and Cons

Advantages

Disadvantages

Renewable resource. Trees grow within 30-120 years.

Lower fire resistance than concrete

Sustainability. Timber has the lowest CO2 footprint compared to steel and concrete.

Bad strength perpendicular to its grain

Lightweight building material

Durability

Easy design for assembly and disassembly

Where are structural timber columns used?

- Family houses

- Sheds

- Cabins

- Canopies

- Small garages

- etc.

6. Circular Concrete Column

I basically grew up this the circular concrete column from the picture above.

It’s supporting the garage ceiling in my parent’s house.

In this case, a circular column was favourable because we wanted to park cars on each side of the column, but we didn’t have a lot of space to open the doors.

Circular concrete columns are not as common as rectangular, due to the reason that they are a bit more difficult to produce.

However, they are in many cases great aesthetic features, don’t you think?

So let’s have a look at the advantages and disadvantages. ⬇️⬇️⬇️

Pro’s and Con’s

Advantages

Disadvantages

Aesthetically pleasing

Concrete is unsustainable, high CO2 emissions during production for cement

Concrete as material is inexpensive

Heavy structure -> bigger foundations are required than for steel or timber

Concrete has great compressive strength properties

Where are circular concrete columns used?

- Housing

- Office buildings

- Garages

- etc.

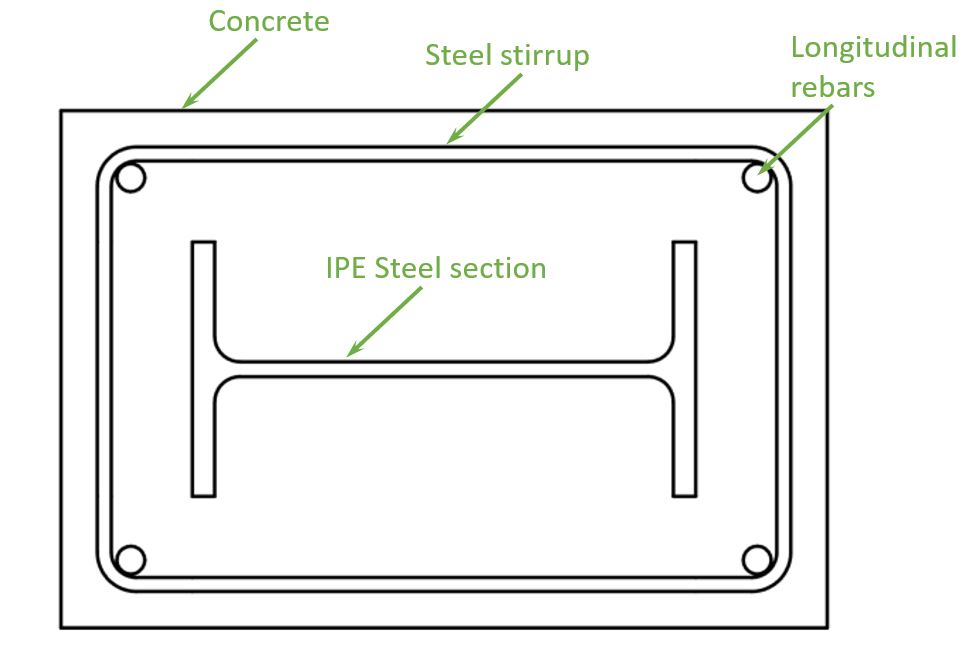

7. Composite Column – Concrete and Steel

An alternative to concrete or steel columns is a mix of it! Composite Columns!👍

In this type of column, a structural steel section is covered by concrete, as the picture above shows.

There are plenty of advantages of this type. Let’s check them out!

Pro’s and Con’s

Advantages

Disadvantages

Increase of strength for the same amount of volume required

Concrete and steel are unsustainable, high CO2 emissions during production for cement and steel. However, utilizing the strengths of both materials, reduces the total material needed

Smaller drying shrinkage compared to conventional concrete columns

Heavy structure -> bigger foundations are required than for steel or timber structures

Good fire and corrosion resistance

Where are composite columns used?

- Housing

- Office buildings

- Garages

- etc.

8. Circular Hollow Steel Column

This type of column isn’t too common. However, it has advantages over the other column types.

Circular steel columns are a great choice when exposed to torsional forces.

What are torsional forces?

Torsion happens when loads are applied with an offset to its centreline.

Pro’s and Con’s

Advantages

Disadvantages

Good bending resistance in both axis

Connection to other steel elements more difficult than with other sections

Can be used as composite column -> Inside of column can easily be filled with concrete

More steel is required for structures than if using conventional sections (I/H)

Great torsional resistance

Maintenance cost due to corrosion protection systems (coatings, paintings)

Easy design for disassembly

Steel has low fire resistance

Where are circular hollow steel columns used?

- Wind turbines

- Canopies

- etc.

Columns Used in Engineering – Static Systems

Now, behind every column in a building there is a static system.

Because we somehow need to know how much load the column has to carry, how we build the connections between columns and how the loads travel to the next column.

So, let’s see what options we have.

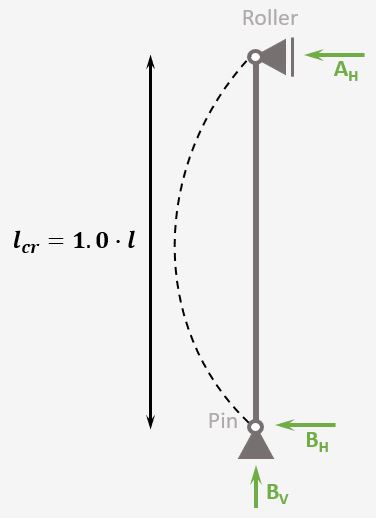

9. Simply supported column

Let’s start with the “easiest” and probably most common steel column – the simply supported column.

This static system is basically a simply supported beam turned 90°.

It’s characterised by a roller and pin support, which results in 3 reaction forces.

For structural engineers, simply supported beams are quite convenient to design, because they are statically determinate, and the forces can be calculated by hand.

Properties of Simply Supported Column

Support types

Roller & Pin

Reactions

Roller: Horizontal

Pin: Vercial & Horizontal

Buckling length

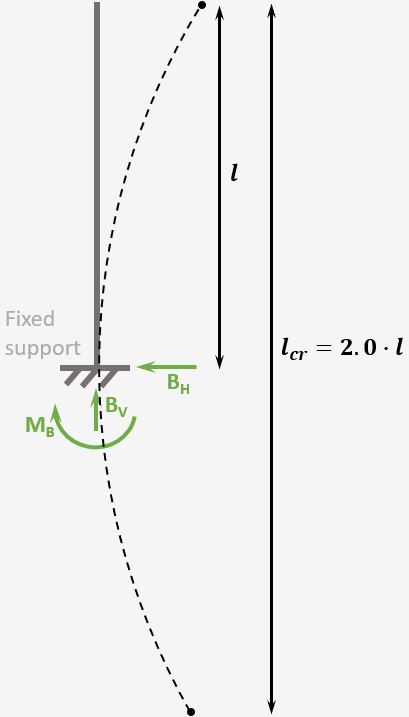

10. Cantilever column

Another statically determinate column is the cantilever column. As for the simply supported column, the internal forces (normal, shear force and moment) can be calculated by hand.

It’s characterised by a single support – a fixed one, which creates 3 reaction forces.

So let’s have a look at some of its properties.

Properties of Cantilever Column

Support types

1 Fixed support

Reactions

Fixed support: Horizontal, Vertical & Moment

Buckling length

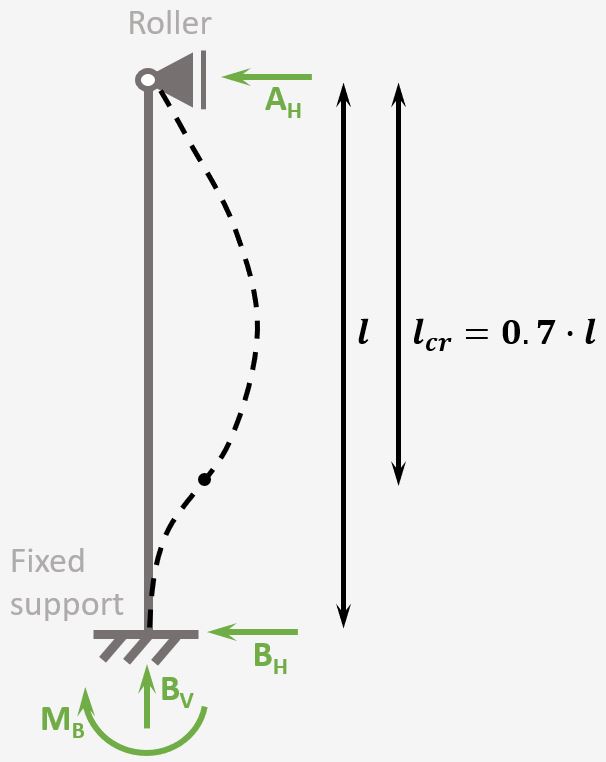

11. Column with 1 Fixed and 1 Roller Support

Now, this static system adds some rigidity and robustness to the whole structure, as it is statically indeterminate.

The internal forces of this column type can’t be calculated by hand any more, and advanced software programs or formulas should be used.

Properties of Column with 1 Fixed and 1 Roller

Support

Support types

1 Fixed support & 1 Roller support

Reactions

Fixed support: Horizontal, Vertical Reaction force & Moment

Roller support: Horizontal Reaction force

Buckling length

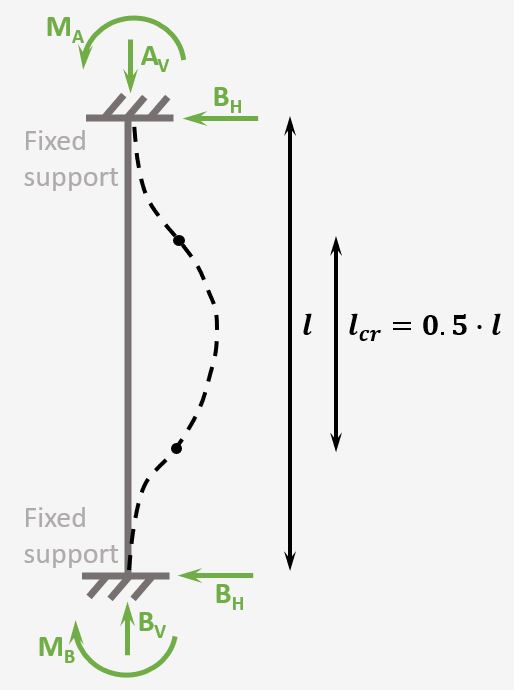

12. Column with 2 Fixed Supports

Now, to add even more rigidity and robustness to our overall structure, 2 fixed supports can be chosen for the static system of the column.

Both supports then have 3 reaction forces each – Moment, vertical and horizontal force.

The internal forces of this column type can’t be calculated by hand any more, and advanced software programs or formulas should be used.

Column with 2 fixed supports

Support types

2 Fixed supports

Reactions

Fixed support: Horizontal, Vertical & Moment

Buckling length

Conclusion

Now, that you got an understanding of what type of columns we use in structural engineering, you can learn about loads, because every column is exposed to loads.

Because there are always multiple loads acting on a column. Considering these different loads in the structural design is done by setting up Load Combinations with safety factors.🦺

Once all load cases and combinations are set up, the structural elements can be designed. We have already written a lot of guides on how to design columns. Check them out.

I hope that this article helped you understand the different types of columns and how to go further from here. In case you still have questions.

Let us know in the comments below ✍️.

Types of Columns FAQ

Columns are vertical structural elements which resist vertical⬇️ and/or perpendicular➡️ loads. Columns are characterized by acting in compression➡️⬅️. However, tension⬅️➡️ and bending are also possible. The loads travel through the elements and get distributed further to the next column, slab or foundation. Columns mostly support other columns, beams and slabs.

The 3 most common columns are

– Rectangular in-situ concrete column

– Glulam timber column

– Steel column with a I/H section

Read the full article to learn about the other types.

![Moment of Inertia Calculation [2025]](https://www.structuralbasics.com/wp-content/uploads/2023/01/Moment-of-Inertia-calculation-768x439.jpg)

![How To Find The Centroid [A Step-By-Step Guide]](https://www.structuralbasics.com/wp-content/uploads/2023/04/How-to-find-the-centroid-of-sections-768x439.jpg)

![Centroid of I Beam: Calculation Example [2025]](https://www.structuralbasics.com/wp-content/uploads/2023/02/Centroid-of-I-Beam-768x439.jpg)